TECHNIQUES and PROCESSES

About The Work

|

Karen produces beautiful, one of a kind kiln-formed glass bowls, plates, and dishes. Each piece is measured and cut by hand, fired in a kiln to nearly 1500 degrees Fahrenheit, and fused together into a solid piece. It is fired again to slump or shape the glass into a form or mold. The glass object is then finished by hand, using traditional cold finish methods of hand-grinding and polishing.

|

Flow Slab Pattern Bars |

Flow Slab pattern bars are created using a multi-step process, from sheet glass, to a thick slab or brick of glass, to sliced pattern pieces. Glass sheet colors are selected, and stacked in a kiln, and melted together, to form a solid brick of glass. The glass brick is then sliced with a tile saw, into thin strips, exposing extraordinary and dynamic patterns. These strips are then incorporated into glass designs. |

Choosing the paletteThe first step for making a flow slab pattern bar, is to pick a color palette, working with complementary colors and good contrast. Glass can be opaque (above), transparent, or a combination of both (below).

|

Sheet glass in the kilnOnce the palette is chosen, the glass is cut, cleaned, and stacked on a kiln shelf, within a brick structure (dam). The dam will keep the glass contained, during the melting process.

|

The SlabThis is what the top of the slab looks like, when it's done with the melting (fusing) process. This slab is ready to be sliced.

|

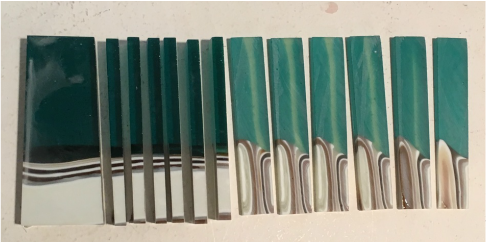

The Slab, sliced

Here is a great example of a flow slab (different color palette) from slab (on the left), sliced (center), and the slices laid flat. This example also shows the use of both opaque glass (creams, browns, and tans), and transparent glass (blue). From here, the slices will be laid out, into a plate or tray design, using similar colors or palettes to compliment the pattern above.